Innovation Spotlight: Hybrid Technology

The hybrid drive system may be the most widely known form of hybrid technology, but it’s not the only one. In fact, several Toro® products use hybrid technology in different ways to gain advantages in power and efficiency. We’ll take a quick look at three examples in this Innovation Spotlight.

Hybrid Drive: The Toro Reelmaster® 5010-H

One example of this idea at work is the Toro Reelmaster® 5010-H — the golf industry’s first fairway mower with a true hybrid drive system. This system, called PowerMatch, pairs a 24.8 hp Kubota® Tier 4 diesel engine with an inline motor generator and a self-charging 48-volt battery pack.

In typical mowing conditions, the Reelmaster 5010-H has ample power from the diesel engine to support both traction and cutting. This allows for plenty of time to keep batteries charged and the system functioning optimally. However, when more challenging mowing conditions demand more power, the battery pack takes the load of the cutting units away from the engine, leaving more available horsepower for the traction circuit.

In more extreme situations where even more horsepower may be required for verticutting or scalping, the batteries take on the cutting unit load and send the reserve battery power back through the motor generator, boosting engine power to the equivalent of over 40 horsepower.

Depending on terrain and cutting conditions, you could see an average fuel savings of 20 percent over a conventional fairway mower (and even more when you choose to run in Economy mode). In addition, the unique design also reduces maintenance time by eliminating all of the cutting units’ hydraulic components.

All-Electric Reels: Toro Greensmaster® TriFlex™ Hybrid Models

Toro’s Greensmaster® TriFlex™ Hybrid series applies hybrid technology in a different way. These gas- or diesel-powered greens mowers feature an all-electric reel circuit that was custom-designed with ample power for the most demanding applications, on and off the green.

In addition to eliminating hydraulic leaks, each highly efficient reel motor has a nominal 1.5 horsepower (1.1 kW) that can increase up to 3.0 hp (2.2 kW) during peak load periods. This translates into the power you need when you need it for the most challenging cutting or verticutting applications.

TriFlex Hybrid models also operate efficiently in energy savings mode. While in this mode, engine RPMs are reduced and the all-electric reel drive maintains a constant reel speed. This results in reduced fuel consumption and noise while maintaining quality of cut, performance and productivity.

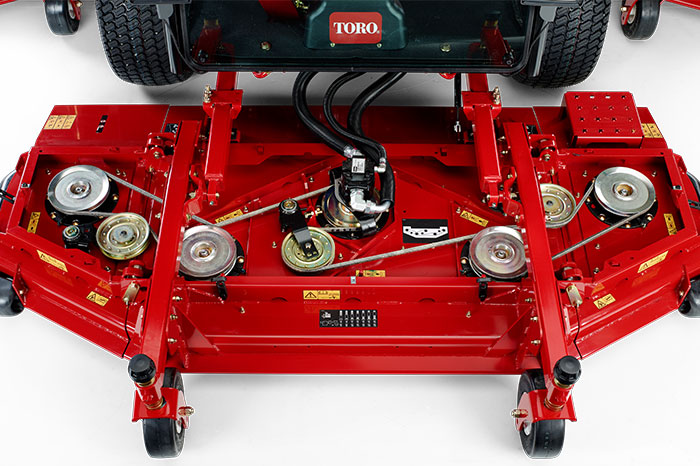

HybridDrive™ Cutting Decks: Toro Groundsmaster® 5900 and 4000

Toro’s Groundsmaster® 5900 and 4000 rotary mowers are yet another example of combining two technologies in a “hybrid” application. These models feature the HybridDrive™ cutting deck system, which combines a hydraulic motor to drive one spindle, with the remaining spindles driven by individual B section Kevlar® v-belts.

Belts transfer power more efficiently than hydraulic motors, while adding a layer of protection against hydraulic failures. In addition, the large-diameter spindle housing dissipates impact loads, and dual tapered roller bearings last up to six times longer than ball bearings. Together, these components are designed for unmatched reliability.

These three examples demonstrate how Toro delivers a range of hybrid solutions, each of which makes the whole greater than the sum of its parts. At Toro, we’re always looking for new and better ways to help our customers increase their productivity — including exploring more hybrid combinations in the future.

Check out the full line of Toro products for the golf industry at toro.com/golf.